Note on scope:

What follows is my professional engineering interpretation of NFPA 70E, OSHA rules, and related standards, based on my experience as a licensed Professional Engineer in electrical power systems.

It’s not legal advice—Elevation Power Engineering isn’t a law firm—but it is my clear recommendation that every facility with energized electrical equipment should maintain an up-to-date arc flash risk assessment. It’s one of the ways to protect workers, simplify PPE requirements, and avoid the dangerous extremes of overprotection or non-compliance.

It's not just a sticker. It's not just a study.

Arc flash risk analysis is a legal and ethical obligation.

If your employees or contractors perform energized work on electrical equipment 50 volts or higher, you are required to assess the risk and document it. This documentation must provide clear guidance to prevent injury or death. This applies whether you own or lease your facility—landlords are technically responsible for providing arc flash studies to tenants, but many don’t know this requirement exists. Lease tenants are also required to assess arc flash hazards of any equipment they add to their space, even if they only hire electrical contractors to service their equipment. More often than not, business owners are simply unaware of arc flash study requirements and don’t know they need to have someone perform a study for their facility.

Keep in mind that even if qualified electrical workers never perform energized work, electrical equipment is assumed “live” until proven otherwise. To establish an electrically safe work condition, workers must test for the absence of voltage on each conductor or circuit part using an adequately rated test instrument. Since the equipment is assumed energized during this testing step, proper arc flash personal protective equipment (PPE) is still required. This means arc flash studies are 100% relevant to all electrical work—even supposedly “de-energized” work.

This isn’t optional for commercial and industrial businesses, and it isn’t a scare tactic. Safe workplace practices keep qualified electrical workers informed on the job and alive to go home to their families without life-altering injuries. The arc flash study and labeling requirements outlined in National Fire Protection Association (NFPA) 70E 2024 are designed to empower employers to protect their employees and contractors in the workplace.

What is an Arc Flash Study?

Plain English, no fluff:

An arc flash study calculates how intense a fireball would be if you accidentally dropped a metal tool onto live electrical parts in an electrical panel, creating a short circuit. Think of it like a lightning bolt trapped in a small space – temperatures can reach 35,000°F (four times hotter than the sun’s surface) in milliseconds creating an intense fireball.

The study tells you what kind of protective gear workers need to reduce the severity of burns and where safe work boundaries should be to protect others from this explosive fireball. Without proper protection, severe burns can occur even 10 feet away from the arc.

An arc flash study produces the following items for businesses:

- A documented risk assessment that qualified electrical workers can reference prior to performing work

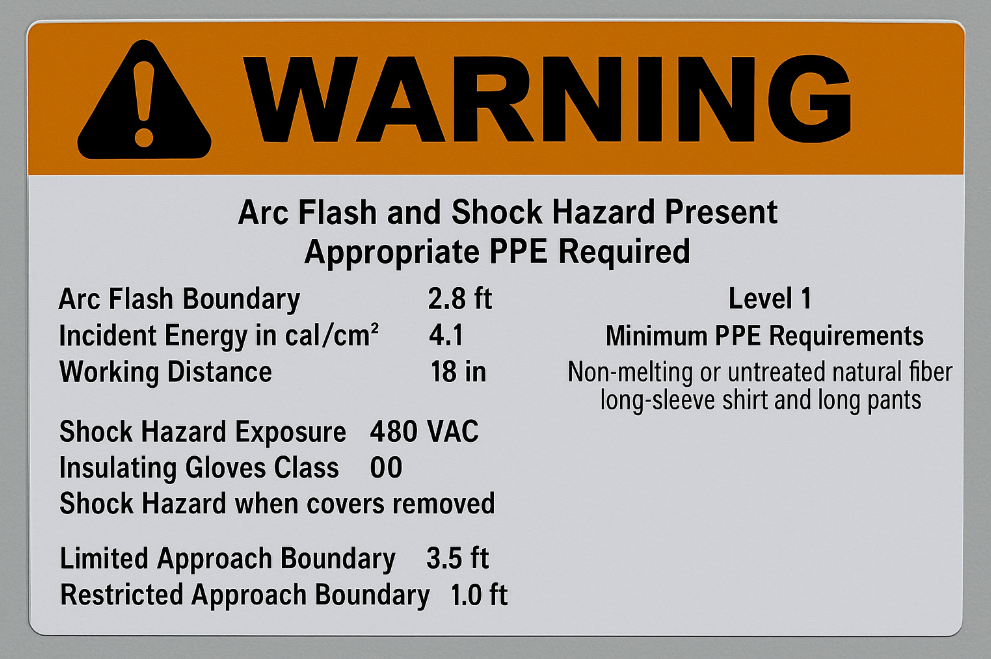

- A printed label for each piece of equipment that indicates the potential fireball intensity (arc flash incident energy), the minimum distance unqualified workers should be kept away from the equipment while the potential for arc flash exists (arc flash boundary), and the operating voltage of the equipment (shock hazard)

The information on the label and in the report allows electrical workers to choose the right PPE for the job, keep other people away from the equipment by setting up danger tape around the work area, and choosing the right tools for the anticipated voltage levels.

It’s important to note that an arc flash study focuses primarily on burn hazards from intense heat. However, arc flash events create additional dangers that aren’t captured in the incident energy calculations: sound levels exceeding 140 decibels (which can cause permanent hearing damage), high-speed molten metal droplets and shrapnel, and intense ultraviolet radiation that can damage unprotected eyes. NFPA 70E provides additional guidance on selecting proper hearing protection, eye protection, and face shields to guard against these secondary hazards at different incident energy levels.

Is This Really Required?

✅ Yes. More businesses are having engineers perform these studies every year—even major retailers like Walmart recognize this isn’t optional.

The Occupational Safety and Health Administration (OSHA) doesn’t enforce NFPA 70E directly—they enforce safety results. NFPA 70E is the industry standard used to meet OSHA’s General Duty Clause, which requires employers to protect workers from known hazards. When someone gets hurt or a citation is issued, OSHA asks one critical question:

“Did you follow NFPA 70E?”

If you didn’t, here’s what you’re facing:

-

OSHA fines issued per panel, per hazard

-

Insurance coverage denial for workplace incidents

-

Personal injury lawsuits from injured workers or contractors

- Seven or eight-figure settlement costs if someone is seriously injured or killed

Your insurance company isn’t just looking at this for compliance—they require you to provide a safe workplace. If they discover you didn’t give your electrical contractors or employees the necessary safety information to work on your equipment, they can deny coverage when you need it most.

The bottom line: Unassessed electrical hazards expose you to catastrophic financial and legal consequences that far exceed the cost of an arc flash study. But the real cost isn’t measured in dollars—it’s measured in the worker who never walks again, the child who grows up without a parent, and the business owner who has to look families in the eye knowing a preventable tragedy destroyed their lives.

Here’s the question that will haunt you: How do you explain to a family that their loved one was permanently disabled because you thought an arc flash study was too expensive or inconvenient?

What Changed in 2024?

Even the most experienced electricians can’t visually determine if an electrical panel will produce a 2 cal/cm² or 20 cal/cm² arc flash. Without an arc flash study, they’re forced to either guess at the right PPE level or wear the heaviest protection available for every task—neither of which is safe or practical.

OSHA recognized this problem and took action. Their April 2024 memo expanded enforcement discretion, meaning inspectors can now issue separate fines for each serious electrical hazard that hasn’t been assessed or documented—including unlabeled or unassessed equipment. The enforcement approach varies by region and case, but it significantly increases the risk for facilities that haven’t done their due diligence.

That means one unlabeled or unassessed panel could lead to a separate fine—especially under OSHA’s expanded enforcement discretion. Ten panels = ten fines. Not fun.

It’s no longer about whether you intended to follow safety standards. It’s about whether your documentation proves it.

What if my Equipment Doesn’t Have Labels?

Even if equipment is labeled, those labels may be invalid if:

• They’re based on outdated studies (older than 5 years)

• The electrical system has changed since the study without re-evaluation

• The label was created without proper engineering review or calculations

• They’re generic “one-size-fits-all” labels that don’t reflect your specific system

Here’s the problem: Without valid labels, electricians are forced to either:

– Assume the worst-case scenario and wear maximum PPE for every task (impractical and often unsafe due to reduced dexterity)

– Make educated guesses about hazard levels (potentially fatal if they guess wrong)

– Refuse to work on the equipment (smart, but doesn’t solve your operational needs)

The OSHA reality: Unlabeled or incorrectly labeled equipment is now a citable offense under the April 2024 enforcement memo. Each piece of unlabeled equipment can result in a separate fine.

Don’t let missing or invalid labels put your workers in an impossible position—and don’t let them put your business at regulatory and legal risk.

What NFPA 70E Actually Says About Labels

There’s a lot of confusion about whether arc flash labels are “optional” based on Exception No. 2. Let’s clear this up by looking at what the standard actually requires.

The main requirement is straightforward: NFPA 70E requires labels on electrical equipment that’s likely to need work while energized. Here’s the exact language from Section 130.5(H):

Electrical equipment such as switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers that are in other than dwelling units and that are likely to require examination, adjustment, servicing, or maintenance while energized shall be marked with a label containing all the following information:

(1) Nominal system voltage

(2) Arc flash boundary

(3) At least one of the following:

– Available incident energy and the corresponding working distance, or the arc flash PPE category in Table 130.7(C)(15)(a) or Table 130.7(C)(15)(b) for the equipment, but not both

– Minimum arc rating of clothing

– Site-specific level of PPE

What equipment needs labels?

NFPA 70E specifically mentions “switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers,” but the reality is much broader. Any electrical equipment that workers might need to examine, adjust, service, or maintain while energized requires labeling.

Common equipment that falls into this category:

Power Distribution:

– Main electrical service panels

– Distribution panels and subpanels

– Transfer switches (manual and automatic)

– Disconnect switches

– Meter centers and instrument transformer cabinets

Motor Control:

– Variable frequency drives (VFDs)

– Motor control centers (MCCs)

– Motor starter panels

– Soft starters and reduced voltage starters

Industrial Controls:

– PLC control panels

– HMI/operator interface panels

– Process control cabinets

– Fire alarm panels

– Security system panels

Important note: Not all industrial control cabinets contain voltages greater than 50V. Many control systems operate at 24V DC or other low voltages that fall below NFPA 70E requirements. However, control cabinets that receive power from higher voltage sources (like 480V panels) or contain mixed voltage systems still require evaluation and labeling.

Specialty Equipment:

– UPS systems and battery backup panels

– Generator control panels

– Elevator control rooms

– HVAC control panels

– Lighting control panels

The key question: Could a worker reasonably need to open this equipment, take measurements, or perform maintenance while it’s energized? If yes, it needs a label.

Don’t forget about: Equipment that’s “normally” de-energized but could be energized during troubleshooting, testing, or commissioning. Even junction boxes that are opened routinely for maintenance should be evaluated for labeling requirements.

Here’s why this matters for “de-energized” work:

Remember that establishing an “electrically safe work condition” requires multiple steps where equipment is still assumed energized. According to NFPA 70E Article 120.6, workers must:

1. Test for absence of voltage on each phase conductor using an adequately rated test instrument

2. Test both phase-to-phase and phase-to-ground at each point of work

3. Verify the test instrument is working before and after each test on a known voltage source

4. Apply temporary protective grounding where induced voltages or stored energy could exist

The critical point: During steps 1-3, workers are interacting with equipment that’s assumed energized until proven otherwise. This means they need proper arc flash PPE based on the equipment’s incident energy level—which comes from your arc flash study and labels.

Without valid labels, electricians performing “de-energized” work are forced to guess at PPE requirements during the most critical safety steps. This is exactly why Exception No. 2 doesn’t eliminate the need for arc flash assessment—it just changes how the information is documented and delivered.

Now, about that exception everyone misunderstands:

“In supervised industrial installations… the information required in 130.5(H)(1) through 130.5(H)(3) shall be permitted to be documented in a manner that is readily available…”

—NFPA 70E-2024, Section 130.5(H) Exception No. 2

Here’s what this does NOT mean: Labels are optional for everyone.

Here’s what it DOES mean: In some tightly controlled facilities with qualified personnel and real-time documentation systems, a written assessment may replace physical labels on equipment.

But here’s the catch: That assessment must still exist. It must be current. And it must be readily available to anyone doing energized work. You’re not eliminating the arc flash study—you’re just changing how the information is delivered.

The reality for most facilities: Unless you have dedicated engineering staff monitoring your electrical systems 24/7 and can guarantee that only highly qualified electrical workers will ever touch your equipment, you need labels.

Additional key requirements:

– The method of calculating and the data to support the information for the label shall be documented

– The data shall be reviewed for accuracy at intervals not to exceed 5 years

– Where the review identifies changes that render the label inaccurate, the label shall be updated

– The label shall be of sufficient durability to withstand the environment involved

– The owner of the electrical equipment shall be responsible for the documentation, installation, and maintenance of the marked label

What Elevation Power Engineering Does

Our core deliverables include:

Technical Analysis:

– Short circuit analysis using IEEE 1584-2018 standards

– Comprehensive arc flash hazard assessments using EasyPower and ArcPro software

– Protective device coordination studies

– System modeling and operating scenario simulations

Safety Documentation:

– PPE recommendations based on calculated incident energy levels

– Engineering-stamped reports that stand up to OSHA inspections, insurance audits, and litigation

– NFPA 70E-compliant labeling specifications

– Hazard mitigation recommendations

Optional Services:

– Onsite equipment labeling and installation

– One-line diagram drafting (AutoCAD and PDF formats)

– Annual electrical safety plan development and updates

– Relay and breaker settings optimization

– Ongoing compliance consulting and training

What makes us different:

You work directly with a licensed Professional Engineer—not a sales team, not technicians, not offshore analysts. Patrick Council, PE, personally performs every study, bringing 8+ years of federal government experience in generator diagnostics, electrical equipment testing, and power system analysis.

Here’s the critical difference: While NFPA 70E doesn’t explicitly require these studies to be reviewed by a PE, ask yourself this: Are you willing to risk it by having someone “wing it,” or do you want someone who takes the job seriously by putting their professional license on the line every single time?

Here’s what that PE stamp means for you: When I stamp a report, I’m taking on professional liability for the engineering analysis. That protects you from claims that you didn’t properly assess the hazards, and it protects your workers by ensuring they have accurate, engineered safety information—not guesswork.

The bottom line: When OSHA shows up, when your insurance company audits, or when you’re facing litigation after an incident, you need documentation that was prepared by a licensed engineer who understands both the technical requirements and the legal implications.

That’s exactly what you get with Elevation Power Engineering—and the professional liability protection that comes with it.

Sleep Better Tonight Knowing You've Done Everything Right

Imagine this: An electrician is working in your facility. They open an electrical panel, check the arc flash label, put on the proper PPE, and complete their work safely. At the end of the day, they go home to their family—whole, healthy, and unharmed.

That’s what proper arc flash assessment delivers: peace of mind that you’ve given workers every tool they need to stay safe.

Don’t leave safety to chance. Contact Elevation Power Engineering today and let a licensed PE protect both your workers and your business with engineering-stamped arc flash studies that stand up to any scrutiny.

Disclaimer: This content reflects Elevation Power Engineering’s professional engineering interpretation of applicable electrical safety standards and requirements. It is provided for informational purposes only and does not constitute legal advice. Elevation Power Engineering is not a law firm and does not employ attorneys. Clients should consult qualified legal counsel for advice on legal rights and obligations.